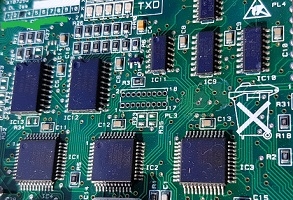

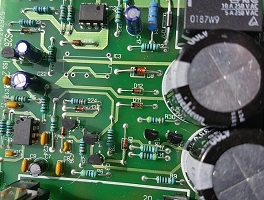

PCB Assembly

Complete Electronics specialises in PCB assembly (PCBA) and using our vast experience of these processes we can deliver right first time and on-time product no matter the complexity of your boards. Flexible quick turnaround. Full or partial turnkey solutions.

- Our Surface Mount (SMT) capabilities encompass SMD component sizes from 1005, 0201 & 0402 packages, etc. to µBGA & BGA (Ball Grid Array), QFN and other fine pitch devices.

- Conventional or through-hole components can be hand or machine inserted. Then hand, wave or even pin in paste soldered. Our experienced staff can advise on the best solutions.

- We are able to process RoHS and Non-RoHS solder components and assemblies via specific controlled processes and soldering solutions.

- PCB technology from single-sided to double-sided multi-layer PCBs. Rigid or Flexi-circuit (Flex).

- Experienced with mixed technology and exotic substrates.

- Conformal coating can be applied to protect PCBs and substrates from thermal shock, moisture, corrosive liquids, and other adverse conditions.

- Potting service is available to protect the PCB from chemicals, moisture, mechanical impact and vibration

- Device programming to your specification can be performed before the manufacturing stage or in-circuit programming post-manufacturing

- Automated Optical Inspection (AOI) which is an automated visual inspection of printed circuit board components and solder joints

- We can assist in design for manufacture and design for test

- A first-off inspection process is performed on each batch built

- We can deliver efficient test solutions and/or customer supplied functional test procedures

Surface Mount PCB Conventional (Through Hole) PCB

Working with our strategic manufacturing partners allows us to select the best solution for your project. Aligning the skills needed to assemble the products economically and quickly to the highest standards. We will include quality inspection at every step of the process to ensure top quality and on-time delivery. We focus on stocking low-cost parts. Where cross-referenced components are required, we will offer you suggestions that will keep your costs as low as possible. While we offer you suggestions, we do not make any final decisions about parts, the final decision is always up to you.

Let us quote for your PCB assembly.

Documentation required to Quote / Build

- Bill of Materials (BOM)

- Printed Circuit Board (PCB) Gerber files

- BOM (xlsx) with manufacturers names (where a specific manufacturer is required), part numbers, reference designators, description and quantity

- Centroid data file

- Additional requirements or instructions

- Test Procedures with pass/fail criteria (If testing is required)