Manufacturing Services

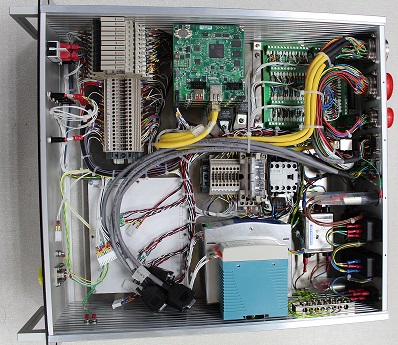

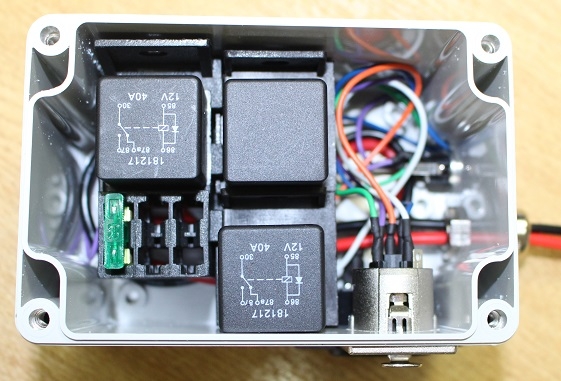

Box-Build

Complete Electronics offer a total logistics solution

Electronics assembly may well be enough for many customers, but more and more customers are looking for a complete solution to include; Full procurement, printed circuit board (PCB) population, cable harnessing, electro-mechanic assembly, test, custom packaging, warehousing, order fulfillment, aftermarket services and repair.

Complete Electronics can offer a "one-stop-shop" solution.

From the Bill of Material (BOM) and drawings, we assemble the electronics and electro-mechanical parts of your product according to your instructions. Our box-build service aims to meet our customer’s expectations in terms of quality and reliability. Complete can control the entire process from the procurement of parts with their own vendors (or clients) to co-ordinate all logistics for building your products at the right time, price and quality.

In short, we are our customer's production and logistics partner to ensure they get their product when they need it.

“Our goal is to reduce cost and improve productivity and manufacturability whilst maintaining quality and reliability to help our customers gain a competitive edge”

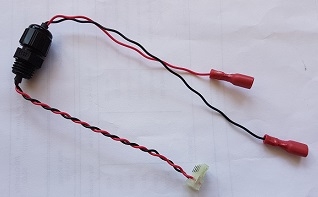

Cable Assembly

A cable assembly/harness is a group of cables or wires that are assembled into a single unit that transmits signals (digital or analogue), electrical power, audio, video and/or data. A cable harness is also known as a wire harness, cable assembly, wiring assembly or wiring loom and offers many advantages over having loose cabling or wiring. By binding or assembling wires and cables together the assembly instantly becomes safer, manageable and more secure. Using a cable assembly, installation time can be significantly reduced in comparison to installing single cables. Our cable assemblies can be terminated with a variety of fixings and connectors and in some cases directly onto a printed circuit board (PCB). Our cable and connector ranges cover a variety of areas including control, data communication, appliance engineering, measurement, heating, industrial ethernet, and factory automation. We also offer a broad line of heat-shrink insulation, plastic spiral binding, braid, and other cable protection products for use in harsh environments and high-temperature applications. For routing of cables and cable assemblies through machine, panel or enclosure walls we have a wide variety of cable management systems with up to IP66 / IP68 and UL type 4X ingress protection. There are several strain relief plates for various mounting methods.

On completion of the cable assembly, each assembly is visually inspected, mechanically inspected and then electrically tested where appropriate to assure a high level of quality for our customers.

We can accept both large volume and small quantity orders. If you prefer to place blanket orders with scheduled shipping dates, we are happy to stock the product for you.

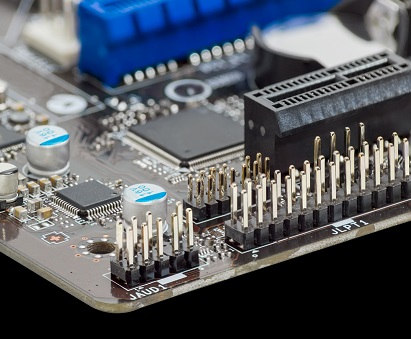

PCB Assembly

Complete Electronics specialises in PCB assembly (PCBA) and using our vast experience of these processes we can deliver right first time and on-time product no matter the complexity of your boards. Flexible quick turnaround. Full or partial turnkey solutions.

- Our Surface Mount (SMT) capabilities encompass SMD component sizes from 1005, 0201 & 0402 packages, etc. to µBGA & BGA (Ball Grid Array), QFN and other fine pitch devices.

- Conventional or through-hole components can be hand or machine inserted. Then hand, wave or even pin in paste soldered. Our experienced staff can advise on the best solutions.

- We are able to process RoHS and Non-RoHS solder components and assemblies via specific controlled processes and soldering solutions.

- PCB technology from single-sided to double-sided multi-layer PCBs. Rigid or Flexi-circuit (Flex).

- Experienced with mixed technology and exotic substrates.

- Conformal coating can be applied to protect PCBs and substrates from thermal shock, moisture, corrosive liquids, and other adverse conditions.

- Potting service is available to protect the PCB from chemicals, moisture, mechanical impact and vibration

- Device programming to your specification can be performed before the manufacturing stage or in-circuit programming post-manufacturing

- Automated Optical Inspection (AOI) which is an automated visual inspection of printed circuit board components and solder joints

- We can assist in design for manufacture and design for test

- A first-off inspection process is performed on each batch built

- We can deliver efficient test solutions and/or customer supplied functional test procedures