Yamaichi Y-Circ M

Y-Circ M

M12 Circular Series

Some of the benefits of Yamaichi’s Y-Circ M

- Produced in Germany to the highest quality and short lead-times at competitive prices.

- Customised assembly available which includes the combination of Y-Con (RJ45) and Y-Circ P (Push-Pull) connectors with UL traceability.

- 360° shielding, vibration & IP68 protection.

- Interference-free transmission with the CAT6A option.

- A, B, D & X-Coded versions available.

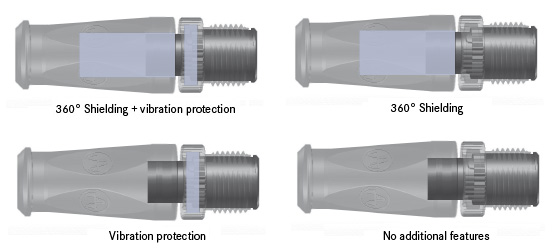

Customer-specific configurations

The Y-CircM series can be individually configured, a modular construction enables optional parts to be added to the connector depending on the customer needs. These options currently include 360° shielding and vibration protection. This variable configuration ensures the best price-performance ratio.

The Y-Circ M series is available in straight and angled forms with A, B, D & X coded options which are compliant with IEC 61076-2-101. There is also an X-coded CAT6A option which will accommodate high-speed interference-free data transmission signals to 10 Gbit/sec and compliments Yamaichi’s other CAT6A Y-Con (RJ45 & USB) and Y-Circ P (Push-Pull) products.

All Yamaichi M12 connectors have IP68 protection and meet the highest standards for contact mating and EMI shielding.

Custom Cable Assemblies direct from the Manufacturer

Yamaichi Electronics is able to offer a wide range of customised cable assemblies that are produced by its production facility in Germany.

Any Y-Circ M connector can be combined as a cable assembly with other Yamaichi products, e.g. the Y-Con or the Y-Circ P product series. These customised cable assemblies are particularly suitable for industrial applications such as the connection of sensor applications to Industrial Ethernet products. If required these cable assemblies can be supplied with a UL traceability label. Yamaichi also manufactures wiring harnesses (ZPFW2) and processed wire (ZKLU/2/7).

The advantages of Yamaichi offering this service are that all the required connector components are available on-site. Therefore the entire cable assembly can be handled at a single production location.

Best Equipment

Yamaichi Electronics Deutschland GmbH equipment includes; automatic cable cutters, automatic crimping systems, compacting systems, electrical test benches, and plastic injection moulding machines for loose and inserted parts.

Another technical innovation allows Yamaichi to implement customer-specific tools for the over-moulding of connectors or special formed parts quickly and flexibly. Based on customer needs and using a standalone software package, the geometric data can be translated from 3D models into the machine code required.

Injection mould tools are manufactured in-house and can be put directly into production. This makes it possible for short throughput times and the manufacturing of cost-optimized tools for small lots.

Cost-Efficient Production

Yamaichi manages the whole process, starting in the concept phase, through the design and material procurement phase, to production and functional test. Add to this a broad range of available products and Yamaichi can guarantee fast flexible handling and high-quality products on short lead-times at competitive prices.